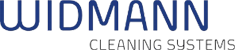

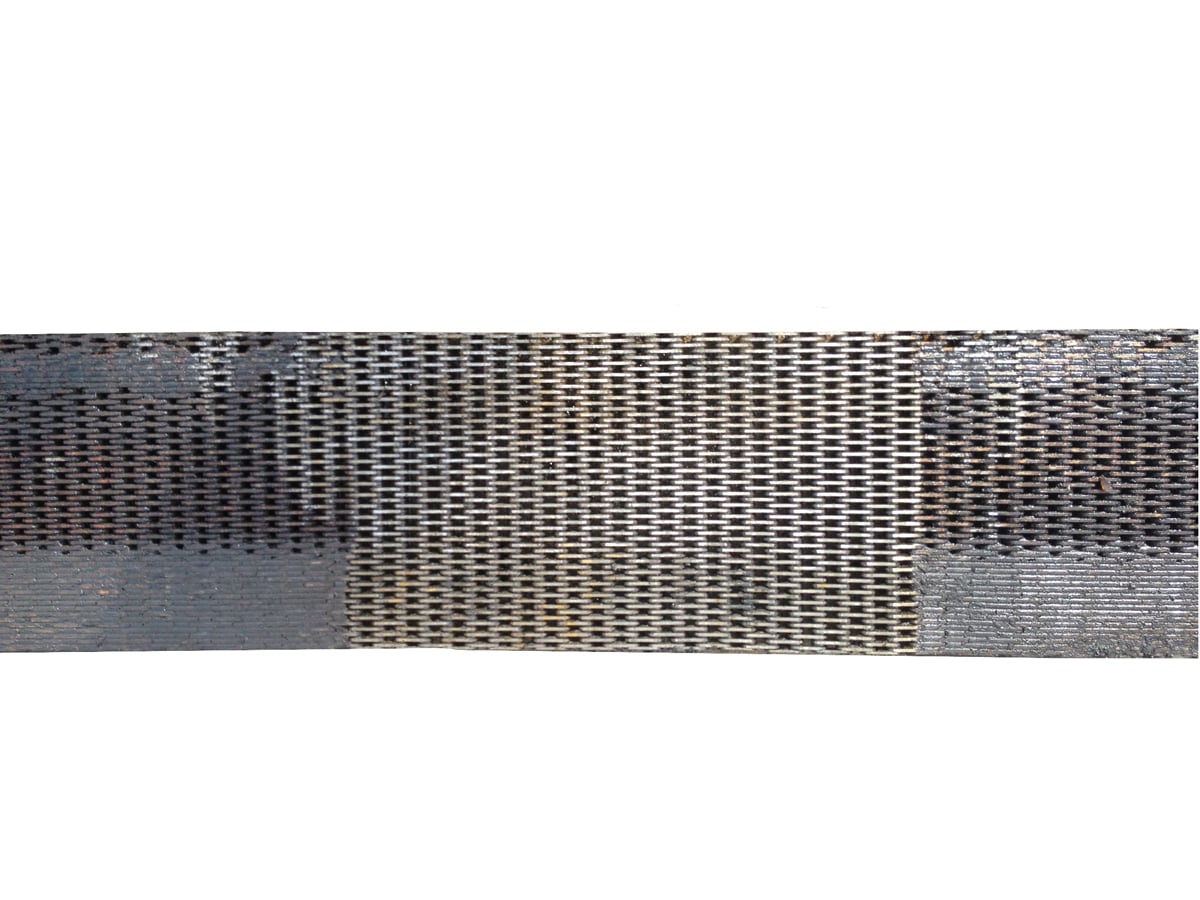

Container glass industrie

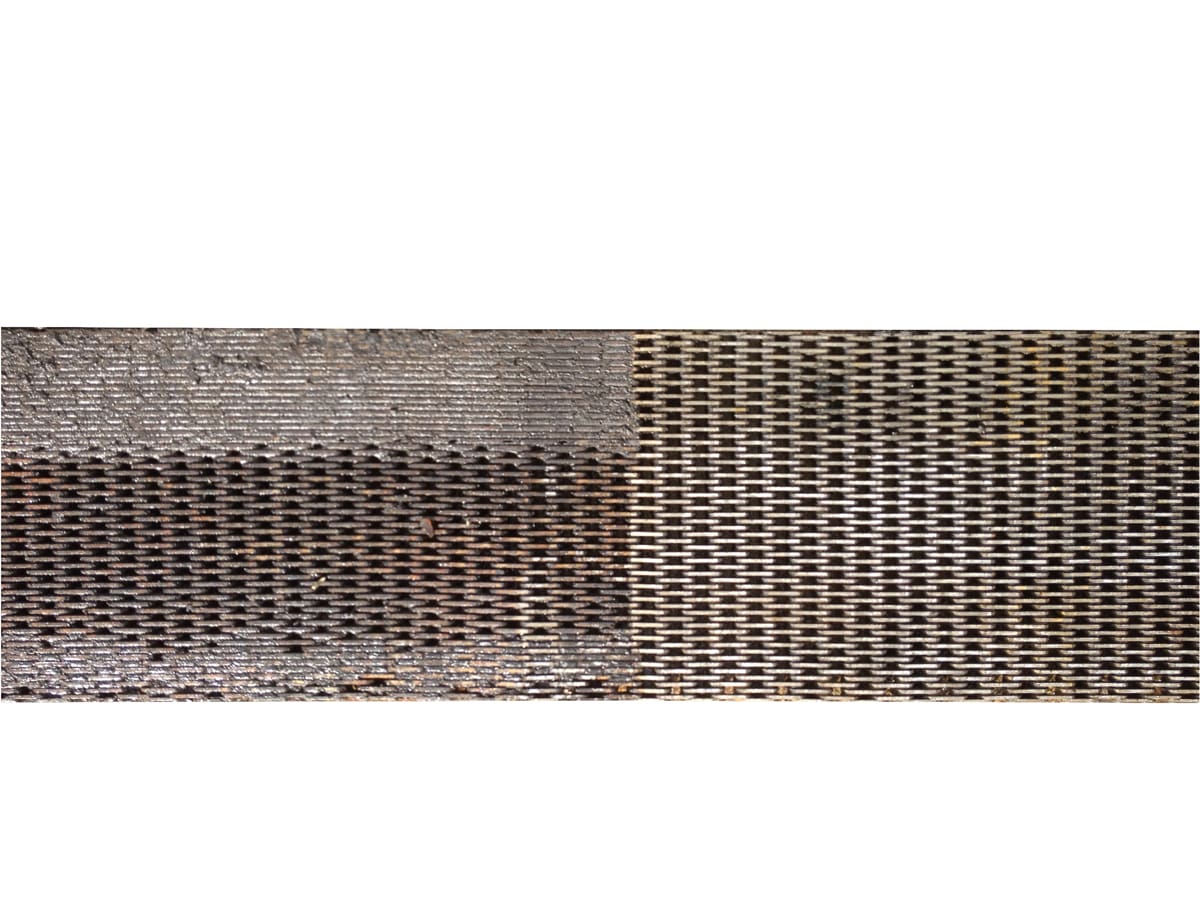

This unique high pressure cleaning system ME 1700 was specifically developed for the requirements of the container glass industry to clean production sights and machine parts as quick, effective and inexpensive as possible. No detergents or other chemicals are required, only pure water is used. Time savings of up to 80%, compared to conventional manual cleaning, are achieved by using this system in the maintenance workshops. Outstanding cleaning results, even the most stubborn dirt from burned-in carbon oil, fats and oils with optimal results. Polluted conveyor belts in the production lines are completely cleaned within a very short time, which has the positive effect that the cooling of the belts is guaranteed again and contamination of the glass containers by the conveyor belt is ruled out.

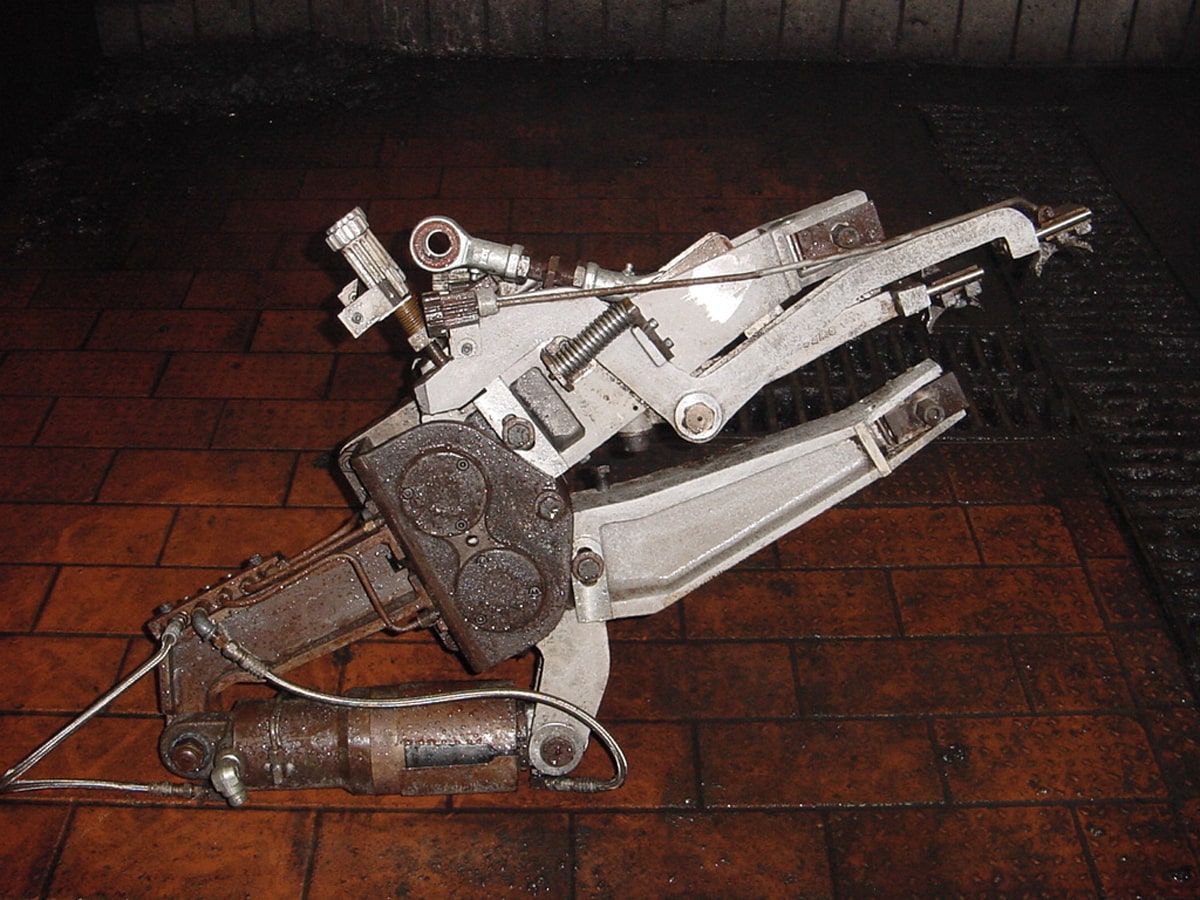

Automotive industry

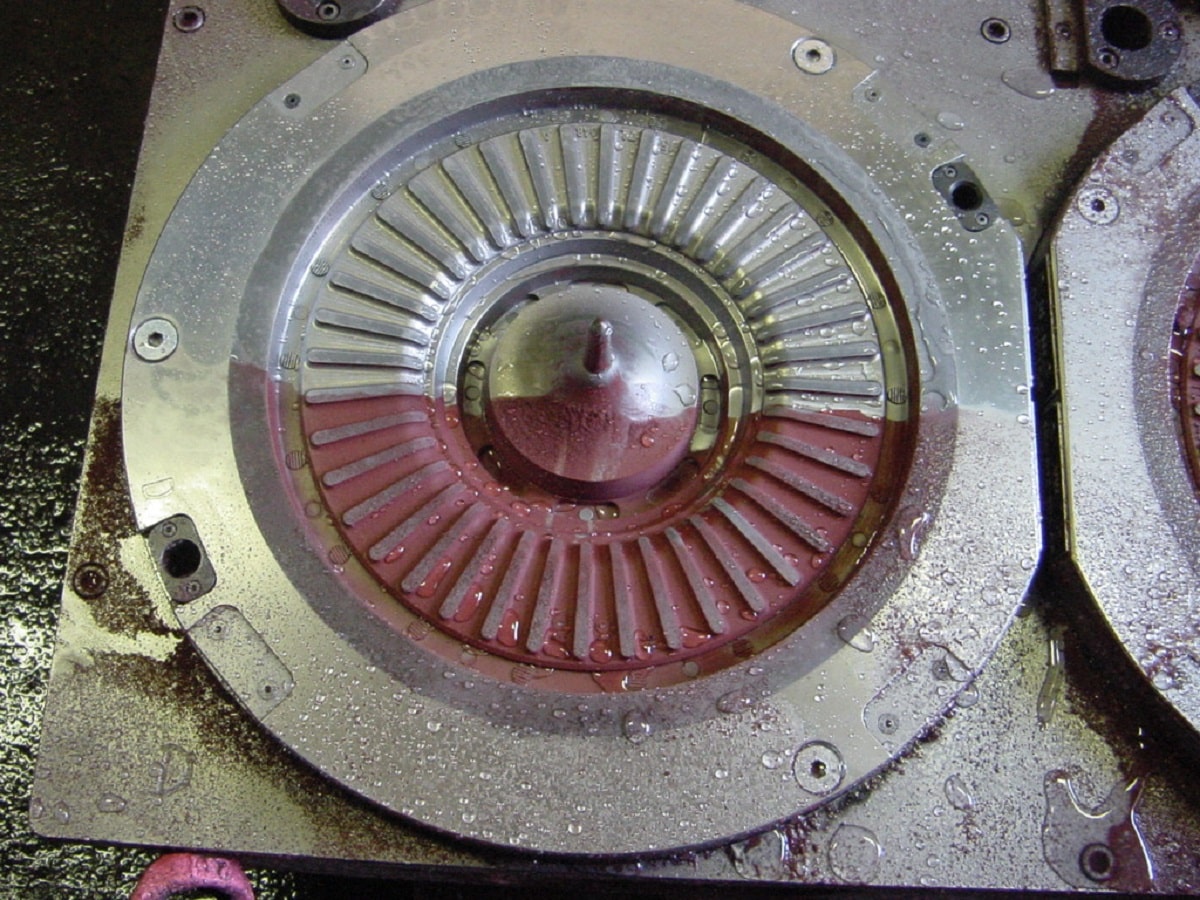

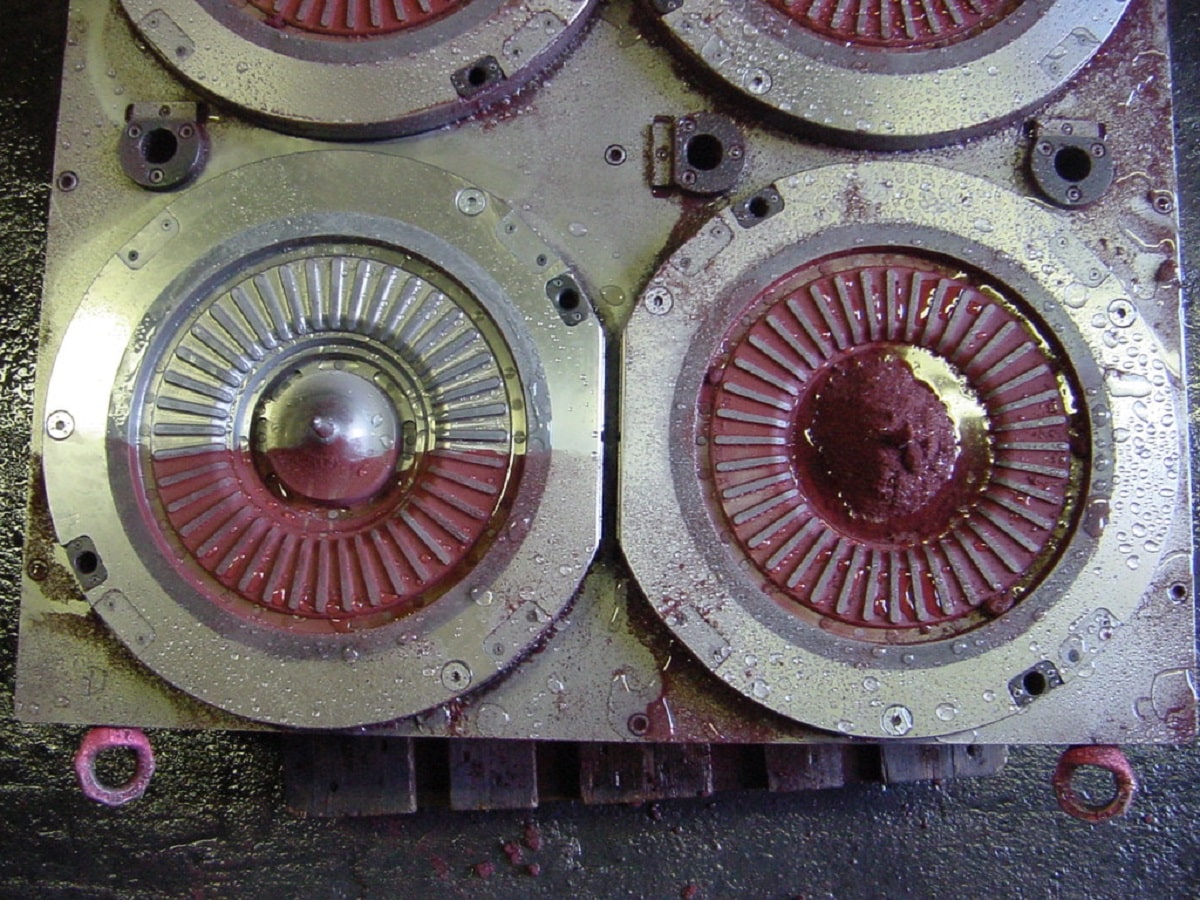

In the production of aluminium and magnesium die-cast parts in the automotive industry, released agent residues on the die-cast molds are completely removed, in the installed state on the die-casting systems. This leads to an enormous reduction in downtime. Finishing and separating coats are also completely removed without the use of chemicals.

Paint and varnish industry

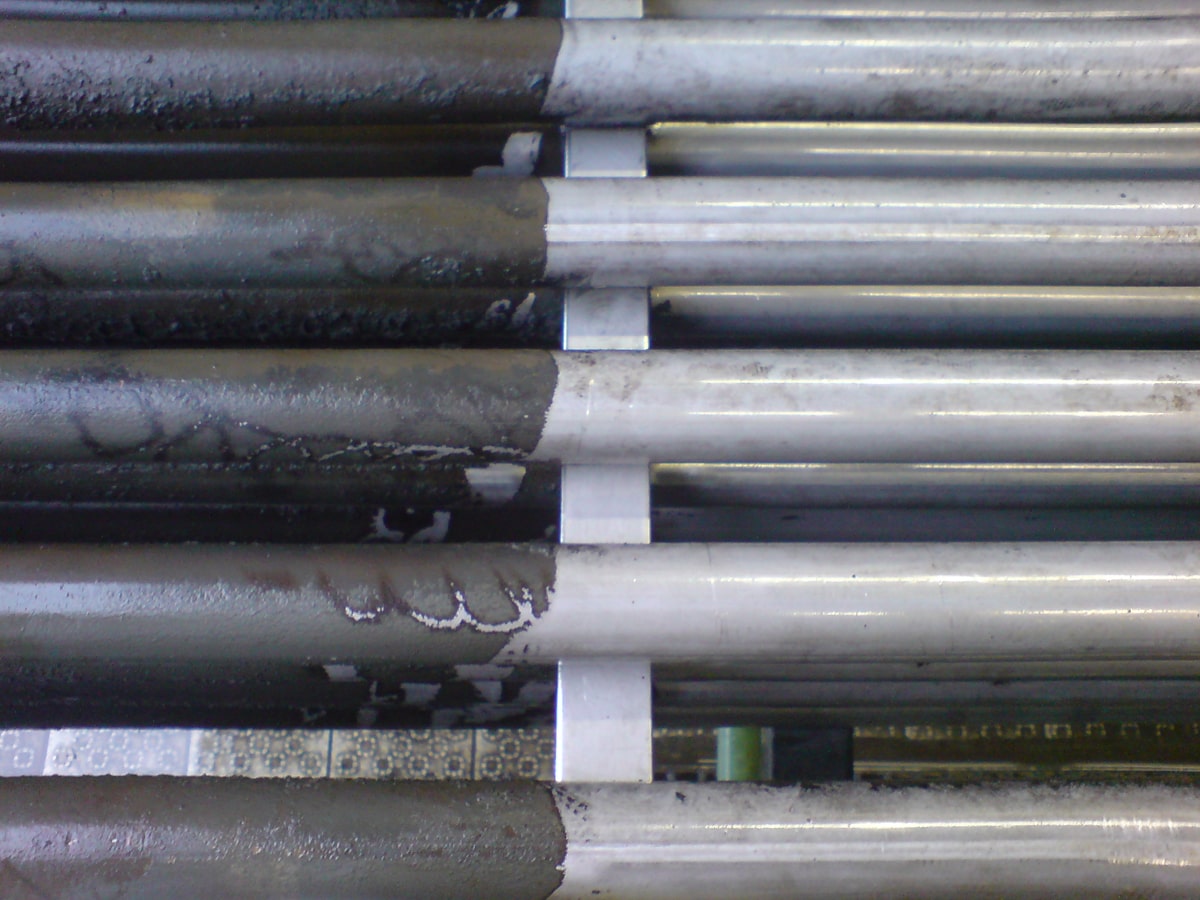

Cleaning of filling systems in paint and varnish production, cleaing of paint tanks, agitators and all system parts without any use of chemicals. Cleaning of extruder screws in the manufacture of powder coatings in the installed state in the production plants reduces downtime during production enormously and leads to high cost savings.